Nano-Focused

The field of nano-optics is unfamiliar to many, due in part to its complexity—and a simple matter of scale.

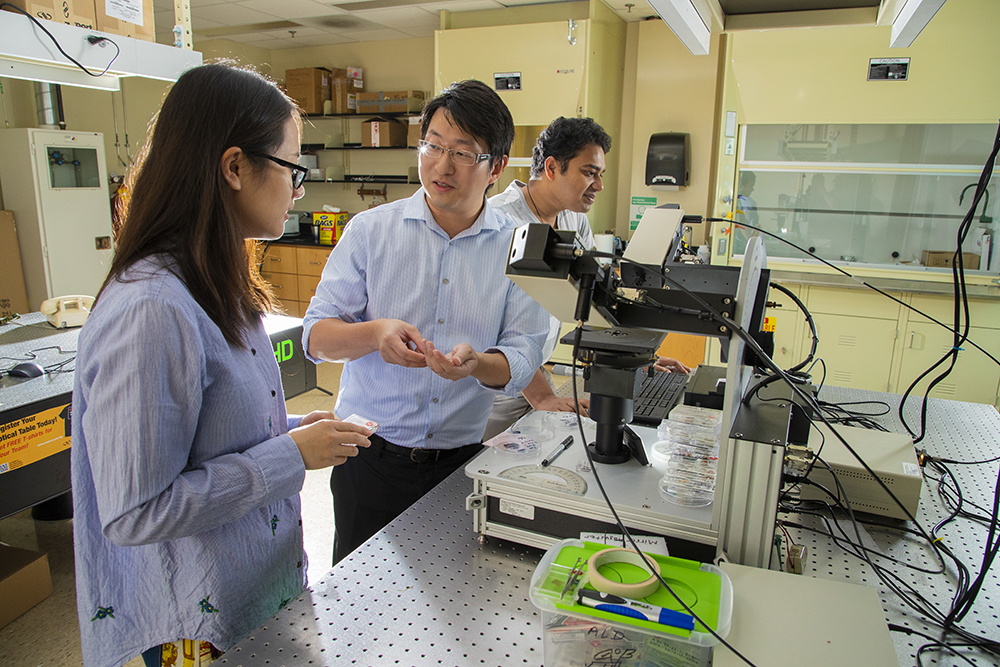

The structures and materials used in the lab of Baylor’s Howard Lee, PhD, an assistant professor of physics, are invisible to the human eye – “10,000 times smaller than our hair.”

While the materials may be miniscule, applied uses for Lee’s research are vast, with high demand for efficient materials and processes across all sectors of science and industry. That demand is what drew Lee into the study of material science and physics.

“We have display screens, optical fiber for communication, lenses, et cetera,” Lee said. “Many of them have been developed and improved for a long time, but the only thing you can really change is the material used. So, in order to find new applications and new devices, you actually need to find some new material. That is the key.”

Enhancing the light

Lee’s work in nano-optical structures and metamaterials is remarkable, moving into a microscopic level of focus that measures down to the two-dimensional level.

“It’s only a few tens atom thick, like a 2-D surface. But more important for me is how we link this material property to the optical property, so this is something we have been working quite a lot on.”

For Lee and other researchers at the intersection of nano-optics and metamaterials, the pursuit of advancements and new discoveries in the field run in a parallel – to change the behavior of the optical properties requires development of new materials that are able to control them.

“Once you’re able to make the material, then we look at the optical properties,” Lee said. “This kind of nanostructure, using the e-beam lithography, makes a pattern on the metasurface that can control the light. This allows us to make lenses, polarized filters, communications or imaging holographs, using this kind of enhancement of the light interaction.”

Developing and growing the metasurfaces opens a new frontier of technology in the sciences of physics and materials. Lee’s work with zero-index materials – those that are only an atom thick – has opened the door for a new generation of technology.

“They’re really in parallel,” Lee said. “You’re doing the optical development, but at the same time, you need to have the material science to support, to get a new innovation and new physics from that. If we have better, new material, you can have a better optical property and new fundamental physics.”

Once the new materials, called “zero refractive index materials," are grown and developed, the focus shifts to improving the function of the optical physics and light-matter interaction on the nanometer scale. The goal is maximum interaction and efficiency.

With interest from all sectors of industry and science, Lee’s approach considers material science advancement, optical improvements and even energy efficiency.

“How can we make it much lower loss? The loss is important for application, but how can we reduce losses on that? At the same time, how can we make it more efficient? For instance, instead of needing 50 volts for active tuning the materials, maybe we can just apply one volt to control the device. This needs to be understood on the material point of view.”

Lee’s work has garnered the attention of his peers in the scientific research community, as well as industry leaders in the fields of physics.

In 2018, Lee was awarded a $500,000 CAREER Award from the National Science Foundation (NSF) for developing the ultra-thin, nanoscale optical films with electrically tunable properties.

The CAREER Award is a highlight among many prestigious honors for Lee, who previously was selected for the 2017 Defense Advanced Research Projects Agency (DARPA) Young Faculty Award and was named in February 2020 as one of 13 SPIE Rising Researchers by the International Society for Optics and Photonics (SPIE).

In a field that trades in the currency of ideas and theories that often go untested or unrecognized, these grants and awards can be just the encouragement a research needs in what can be an unforgiving and ruthless pursuit of science, and a competitive process for grant funding.

“If you get an award like this, it will help to apply for other grants since it shows that you’re established and have formed the research foundation capability. In the U.S., funding is a challenge we’re always seeking to overcome in research. We only have 10 percent success rates, for example. So, it’s great to have something get accepted and to be told the idea you’re doing could be useful for the program manager.”

A clean room

As Baylor has announced its pursuit of R1 status as a top-tier research institution, a major component of that endeavor is to improve the research facilities and laboratories available to faculty to produce many of the kinds of breakthroughs that Lee and his nano-optics lab have been able to accomplish.

One of the priority facilities is a cleanroom and fabrication capability— a completely controlled and sterile environment that allows for optimal production of Lee’s metamaterials.

“When you’re making materials that are so small and thin and high quality, you don’t want to have any impurities, like dust, on your sample. That’s what this clean room environment is able to do, limiting dust particles in the space. That means when you take out the sample, you’ll not contaminate it.

“But I think the bigger thing is if you have all of the capabilities you need to grow the materials for nanofabrication, basically you can make all of the material that would be useful not only for material science, but also for optics, for electronics, for mechanical science, et cetera.”

The clean room, coupled with the e-beam lithography machine and other equipment in Lee’s lab will put Baylor among the best labs in the country.

“This e-beam lithography machine is one of the best in Central Texas,” Lee said. “The clean room is a great start, but we hope to move forward with even more equipment inside the room as well.”

Baylor’s pursuit of R1 status will cast a wide net over the University’s faculty, with researchers across campus securing the funding and facilities that factor in to the myriad markers that the Carnegie Institute evaluates for the grading system.

Advancements like the clean room will be a cornerstone in the campaign Baylor is developing towards that pursuit.

“If we want to become a R1 institute, the research is definitely important,” Lee said. “If you don’t have the facility or resources to do research, it’s hard to compete with other schools. We want to make something good and good resources are really important. The better the equipment could also link to a better research outcome.

“So, this is why we’re moving towards R1, competing with all the others – top-100 schools, top-50 schools. Good resources and good facilities are encouraging to us to do good research. We want to move forward and even extend that progress.”