Lung-on-a-Chip: Analyzing Advanced Materials and Health

Click here for a video look into Christie Sayes' interdisciplinary research.

At the intersection of toxicology and materials science, a Baylor professor is working to keep servicemen and women healthy as advanced materials presented uncharted opportunities on airplanes, automobiles and more.

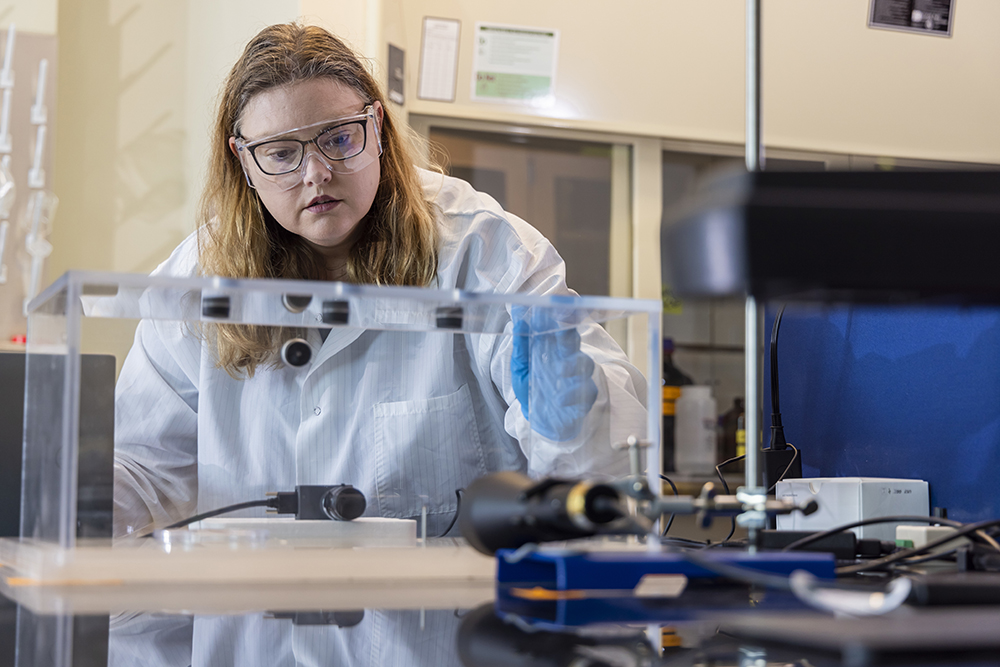

Christie Sayes, Ph.D., associate professor of environmental science at Baylor and faculty fellow in the U.S. Air Force, has developed a “lung-on-a-chip” to simulate the human lung and the ways it is impacted in real operational environments. The chip, like her broader research, bridges technology and health. As advanced materials such as carbon fibers become more common, Sayes examines the impact of aerosols from those materials that can be breathed in by military and civilian personnel.

“Engineered nanomaterials have so much potential to improve on many aspects of everyday life, but we don’t exactly know how they interact with humans and their environment,” Sayes says. “So, we study those interactions to protect the people around them.”

INTERACTING WITH NEW TECHNOLOGY

Sayes’ training in pulmonary toxicology hones her health focus on the lung. In her Baylor lab, she and her students further study emerging technology. These technologies can improve everyday life and are naturally of interest to a variety of industries and organizations, from the commercial aerospace industry to the Department of Defense. They present opportunities for products that are safer and more efficient. With each technological breakthrough, Sayes’ group asks a further question: how do they impact the people working on and around them?

Her work with the DoD began at a Society of Toxicology meeting, where she was introduced to Saber Hussain, Ph.D., Wright State University professor and Air Force Research Fellow. Their conversation spawned questions and, back in their labs, further collaborative research.

“The physical and chemical properties that are different in advanced materials as compared to conventional materials also translate into biological differences,” Sayes says. “We don’t know exactly how these engineered nanomaterials interact with humans and the environment around us. So, we ought to think about those interactions and evaluate the safety as they interface and interact with military personnel.”

Carbon fibers found in many airplanes provide a useful example of her work. At times, repairs will be necessary and the materials will experience natural wear and tear. As they wear down, toxicants could be inhaled by the people working on them through the form of aerosol spray, as particles suspended in the air enter their breathing space.

Information on the impact of these aerosols can be utilized in a variety of ways: personal protective equipment could be developed or required when repairs are taking place, exposure limits and more. To accomplish this understanding, a realistic simulation is needed.

LUNG-ON-A-CHIP

Sayes’ advancements model pulmonary models to study lungs under normal conditions, extreme operational conditions and more, gleaning information that is predictive of lung response to different aerosols. The data can yield insights into recovery time, resilience and more.

“The lung-on-a-chip technology simulates effects the human lung may see in a real operational environment,” Sayes says. “We use the technology to screen for different aerosols that may or may not be in the operational environment to determine if there is an adverse health effect.”

The chip replicates conditions of the human long in a micro-environment which consists of both epithelial cells, which line the airway of the lung, and immune cells, which dictate both sustained and short-term reactions to aerosols introduced into the airways. The technology provides baseline understanding of lung function, data which can be for further benefit—negative impacts aren’t all she seeks to uncover. The technology further provides information to see if lung function can be improved. Repeated tests provide insight into short-term and long-term exposure to aerosols and provide the DoD with upstream approaches—to mitigate those effects and improve on pulmonary function and performance.

“It is beneficial to look for ways to improve upon the function of the lung in two ways. This makes military readiness more accessible, as well as helping us understand the ability of the lung to recover after exposure that might have caused an adverse reaction.”

TECHNOLOGY AND HEALTH

As Baylor University blazes new trails in research, the challenges faculty seek to solve are interdisciplinary in nature. The University’s strategic plan, Illuminate, features five signature academic initiatives—strategic areas in which Baylor researchers can build on University strengths to address problems in areas of national and global importance. Health and Materials Science are two of those initiatives—and they are right in Sayes’ wheelhouse.

“I’m excited about this project,” Sayes says. “We get to understand the benefits that advanced engineered materials offer to the military and other industries, and we also get to understand the safety and effects, both positive and negative, that engineered nanomaterials and emerging technologies provide.”